Product

- Detachable plate heat exchanger

- Domestic plate heat exchanger seal gasket

- Semi welded plate heat exchanger

- Brazed plate heat exchanger

- Welded plate heat exchanger

- Detachable frame

- Heat recovery / heat exchange unit

- Wire winding hydraulic press

Hot news

Semi welded plate heat exchanger

Semi welded plate heat exchanger

Advantages of OMG 's semi - welded plate heat exchangers

* For a variety of critical media have a strong compatibility for the gasket on the erosion of the medium and high pressure running medium.

* Disassembly is simple, can be sealed gasket closed plate for cleaning or cleaning or plate group replacement.

* By increasing or decreasing the number of plates can be very convenient to adjust the heat transfer capacity.

* Fluid stagnation less, the changes in the operating conditions of rapid response.

* Special process laser welding seal and high pressure structure design to seal higher, more pressure capacity

The Advantages of OMG Semi - Welded Plate Heat Exchanger in Conventional Refrigerant Heat Transfer

* Advanced technology, reliable operation. Can avoid secondary heat transfer, low cost, high heat transfer efficiency, heat transfer.

* Simple installation and easy maintenance. Can be cleaned and repair, long life, low operating costs.

* Plasticity is strong and flexible. Can be increased or reduced by the plate group to adjust the amount of heat.

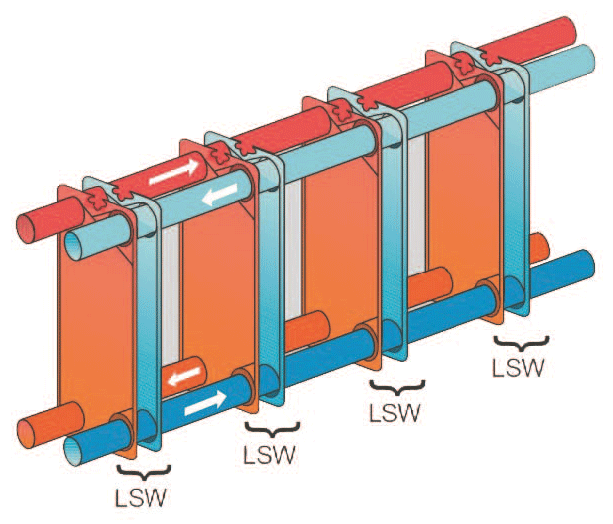

Thermal isolation technology

Jiangsu OMG LSW series of semi-welded plate heat exchanger in the work process can ensure 100% of the flow channel isolation, the critical medium in the flow of the seal after the flow, the heat transfer to the other side of the general medium, Strict isolation design, many industrial processes will not be achieved.

Unique runner design

The unique flow path design can increase the flow of media into the plate heat exchanger when the flutter strength, enhance the heat transfer effect and reduce the corresponding pressure loss. Even if the medium flow rate in the heat exchanger is very low, can also get a high heat transfer effect, in order to meet the requirements of different conditions, we have a variety of plate type to choose from.

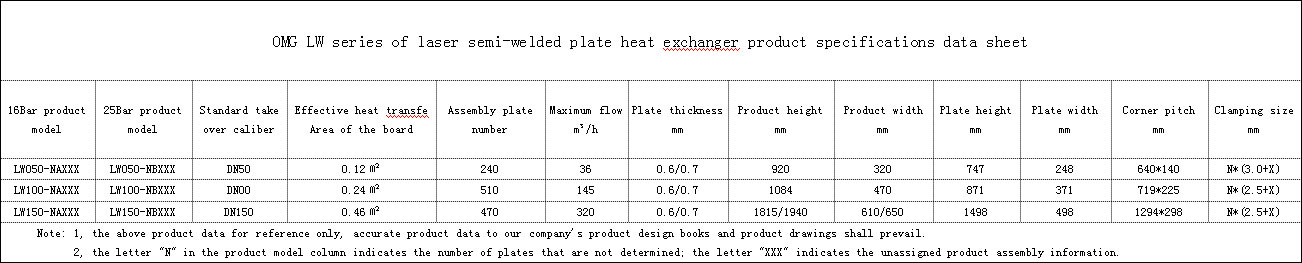

Ougege LW series of laser semi-welded plate heat exchanger product specifications data sheet

* For a variety of critical media have a strong compatibility for the gasket on the erosion of the medium and high pressure running medium.

* Disassembly is simple, can be sealed gasket closed plate for cleaning or cleaning or plate group replacement.

* By increasing or decreasing the number of plates can be very convenient to adjust the heat transfer capacity.

* Fluid stagnation less, the changes in the operating conditions of rapid response.

* Special process laser welding seal and high pressure structure design to seal higher, more pressure capacity

The Advantages of OMG Semi - Welded Plate Heat Exchanger in Conventional Refrigerant Heat Transfer

* Advanced technology, reliable operation. Can avoid secondary heat transfer, low cost, high heat transfer efficiency, heat transfer.

* Simple installation and easy maintenance. Can be cleaned and repair, long life, low operating costs.

* Plasticity is strong and flexible. Can be increased or reduced by the plate group to adjust the amount of heat.

Thermal isolation technology

Jiangsu OMG LSW series of semi-welded plate heat exchanger in the work process can ensure 100% of the flow channel isolation, the critical medium in the flow of the seal after the flow, the heat transfer to the other side of the general medium, Strict isolation design, many industrial processes will not be achieved.

Unique runner design

The unique flow path design can increase the flow of media into the plate heat exchanger when the flutter strength, enhance the heat transfer effect and reduce the corresponding pressure loss. Even if the medium flow rate in the heat exchanger is very low, can also get a high heat transfer effect, in order to meet the requirements of different conditions, we have a variety of plate type to choose from.

Ougege LW series of laser semi-welded plate heat exchanger product specifications data sheet

蘇公網(wǎng)安備32028102001776

蘇公網(wǎng)安備32028102001776