Product

- Detachable plate heat exchanger

- Domestic plate heat exchanger seal gasket

- Semi welded plate heat exchanger

- Brazed plate heat exchanger

- Welded plate heat exchanger

- Detachable frame

- Heat recovery / heat exchange unit

- Wire winding hydraulic press

Hot news

Detachable plate heat exchanger

E series of removable plate heat exchanger

The Characteristics of Jiangsu Ougege E Series Detachable Plate Heat Exchanger

1, advanced shunt structure design, so that more uniform diversion. Jiangsu Oumai grid plate design has a unique shunt structure, so that the media in the entire board evenly distributed flow to improve the heat transfer efficiency, eliminating the dirt accumulation area.

2, parallel flow of the plate design to maintain more convenient. Parallel flow, pipe links to better layout, reducing the plate and pads of the prepared species. Installation and equipment maintenance more convenient.

3, the unique pad structure, so that maintenance faster. Special gasket protects the gasket from being squeezed out to protect the gasket from longer service life. The roof geometry enhances the ability to resist pressure and shock resistance, longer sealing times, longer endurance, and reduced maintenance costs. Special design of the gasket double-channel sealing and signal hole structure, can ensure that the gasket damage, the media leakage from the first seal, through the signal hole and early detection of leakage problems to be resolved in time, will not cause two kinds of heat transfer Medium mixing, to avoid and reduce the loss caused by media leakage. Snap and button-free gasket for gasket life longer, more quick and easy to replace, greatly reducing maintenance costs and maintenance downtime. Sealing gasket is separated from the fixing function, and even if a part of the fixed function of the buckle or buckle failure, the gasket can still play a role in the gasket slot.

4, superior clamping bolt system, so that maintenance easier. Unique and superior clamping bolt system consists of bearing box system, bolts, locking system composed of three parts. The bearing housing system allows the bolts to be quickly and accurately seated and easy to tighten, and the locking system prevents the bolts from rotating when tightened. All bolts are made of roller and coated with anti-corrosion materials and lubricants, plastic cover coat, heavy hexagonal nuts to make the whole dismantling process easier, and all the clamping bolts can be removed from the side of the installation and installation, so that more favorable demolition.

5, accurate multi-point positioning system to maintain more simple. Ougeige detachable plate heat exchanger uses an accurate multi-point positioning system. Corner hole diameter of 100mm the following models of the four-angle positioning system, so that the upper and lower guide plate for the axis of precision embedded together. Corner hole diameter of 150mm or more models of the five-point positioning system, so that the positioning of the plate is a number of metal and metal contact points to determine, in which the upper guide rod contact point, can prevent the plate up and down, the next guide rod contact Point can limit the board will not move left and right. The use of multi-point positioning technology, so that the plate can not move on the guide bar before and after the resistance, easy and simple to complete the maintenance operations, but also in the preparation of the plate when the precise fitting, so that the gasket seal accurate, Poor, plate group to achieve a complete reset, thus ensuring the heat exchanger after the end of life and more durable. And a multi-point positioning system of the plate heat exchanger only need a person, even without any experience, with a simple tool can easily disassemble the heat exchanger, which is other plate heat exchanger products unparalleled.

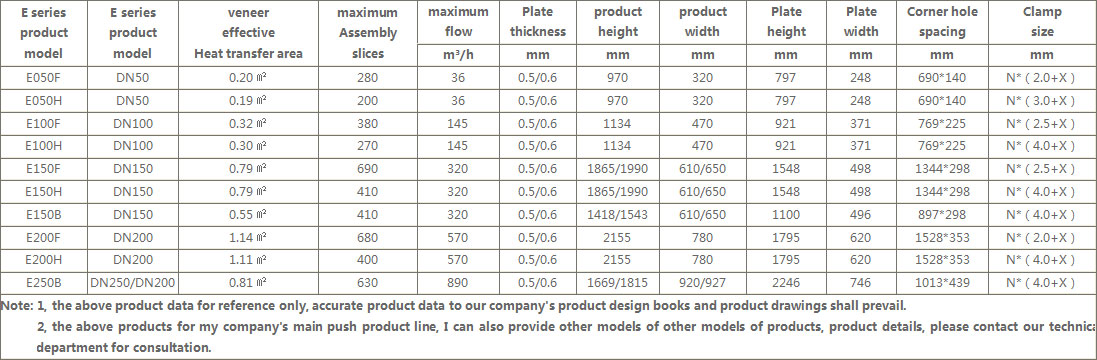

E Series Detachable Plate Heat Exchanger Product Specification Data Sheet

1, advanced shunt structure design, so that more uniform diversion. Jiangsu Oumai grid plate design has a unique shunt structure, so that the media in the entire board evenly distributed flow to improve the heat transfer efficiency, eliminating the dirt accumulation area.

2, parallel flow of the plate design to maintain more convenient. Parallel flow, pipe links to better layout, reducing the plate and pads of the prepared species. Installation and equipment maintenance more convenient.

3, the unique pad structure, so that maintenance faster. Special gasket protects the gasket from being squeezed out to protect the gasket from longer service life. The roof geometry enhances the ability to resist pressure and shock resistance, longer sealing times, longer endurance, and reduced maintenance costs. Special design of the gasket double-channel sealing and signal hole structure, can ensure that the gasket damage, the media leakage from the first seal, through the signal hole and early detection of leakage problems to be resolved in time, will not cause two kinds of heat transfer Medium mixing, to avoid and reduce the loss caused by media leakage. Snap and button-free gasket for gasket life longer, more quick and easy to replace, greatly reducing maintenance costs and maintenance downtime. Sealing gasket is separated from the fixing function, and even if a part of the fixed function of the buckle or buckle failure, the gasket can still play a role in the gasket slot.

4, superior clamping bolt system, so that maintenance easier. Unique and superior clamping bolt system consists of bearing box system, bolts, locking system composed of three parts. The bearing housing system allows the bolts to be quickly and accurately seated and easy to tighten, and the locking system prevents the bolts from rotating when tightened. All bolts are made of roller and coated with anti-corrosion materials and lubricants, plastic cover coat, heavy hexagonal nuts to make the whole dismantling process easier, and all the clamping bolts can be removed from the side of the installation and installation, so that more favorable demolition.

5, accurate multi-point positioning system to maintain more simple. Ougeige detachable plate heat exchanger uses an accurate multi-point positioning system. Corner hole diameter of 100mm the following models of the four-angle positioning system, so that the upper and lower guide plate for the axis of precision embedded together. Corner hole diameter of 150mm or more models of the five-point positioning system, so that the positioning of the plate is a number of metal and metal contact points to determine, in which the upper guide rod contact point, can prevent the plate up and down, the next guide rod contact Point can limit the board will not move left and right. The use of multi-point positioning technology, so that the plate can not move on the guide bar before and after the resistance, easy and simple to complete the maintenance operations, but also in the preparation of the plate when the precise fitting, so that the gasket seal accurate, Poor, plate group to achieve a complete reset, thus ensuring the heat exchanger after the end of life and more durable. And a multi-point positioning system of the plate heat exchanger only need a person, even without any experience, with a simple tool can easily disassemble the heat exchanger, which is other plate heat exchanger products unparalleled.

E Series Detachable Plate Heat Exchanger Product Specification Data Sheet

蘇公網(wǎng)安備32028102001776

蘇公網(wǎng)安備32028102001776